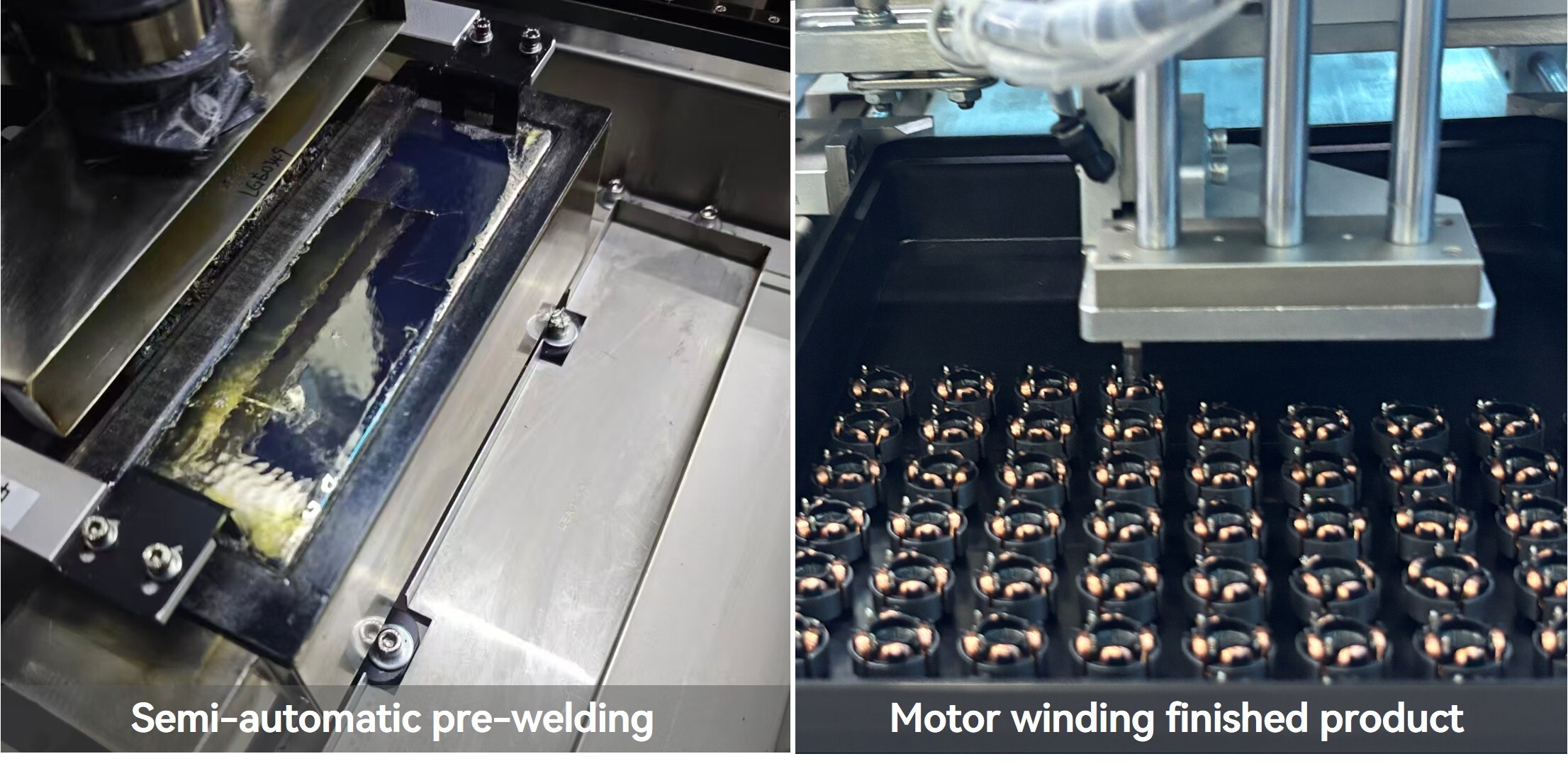

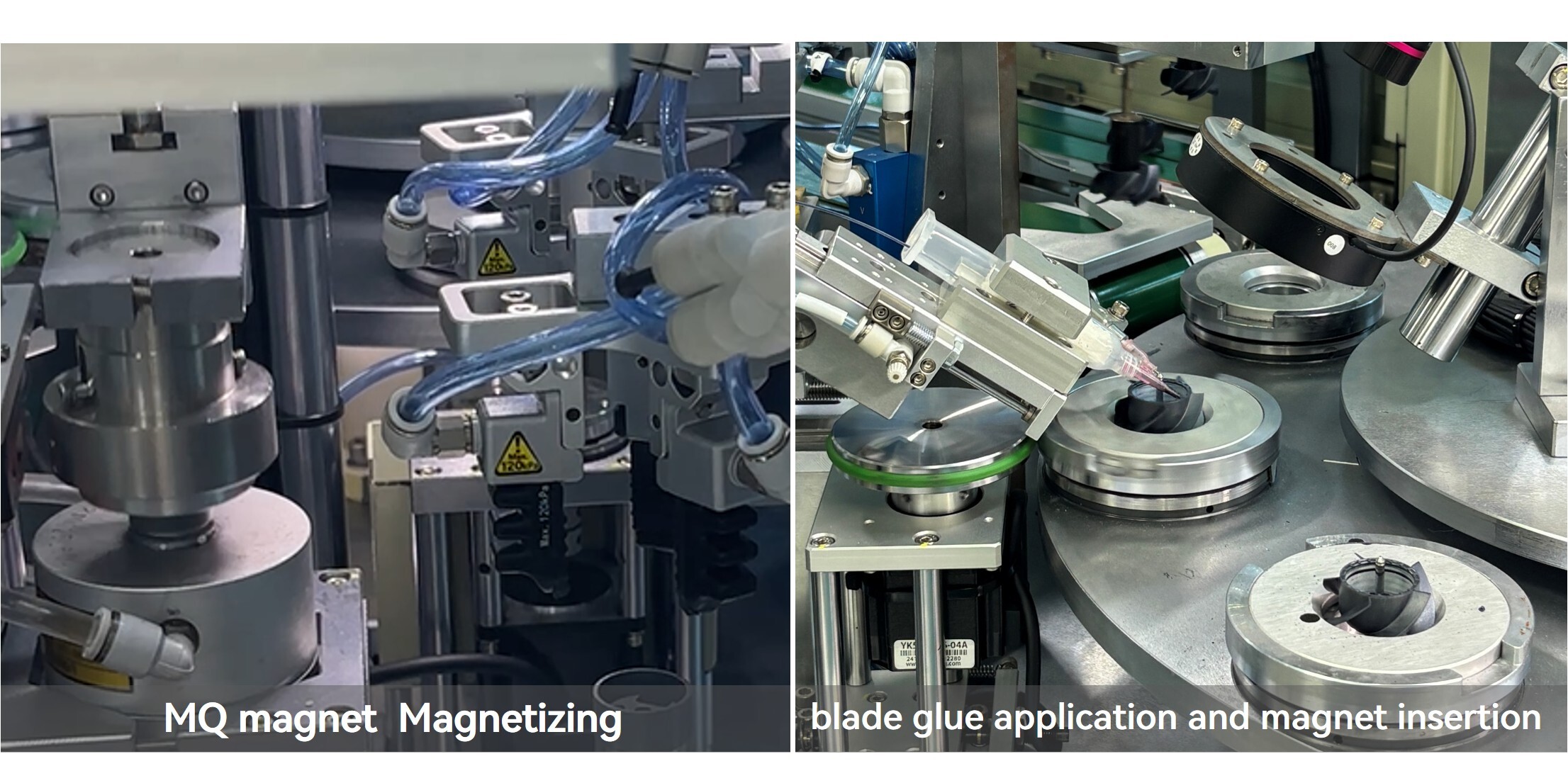

HUAZHUN continues to elevate its high-quality manufacturing by integrating automated production, digitalized management, and full product data traceability. Our automated production lines enable end-to-end assembly and inspection—from raw materials to finished products. Our automated production lines enable end-to-end assembly and inspection from raw materials to finished products.Minimizing human intervention and ensuring precise, unified quality control. At the same time, our automation equipment and standardized quality management system allow us to rapidly deploy and scale new manufacturing sites across diverse regions. This agility ensures that every HUAZHUN facility delivers consistent performance, efficiency, and reliability from day one.